What is Free Coating Manufacturing for Carbon Fiber Bicycle Rims?

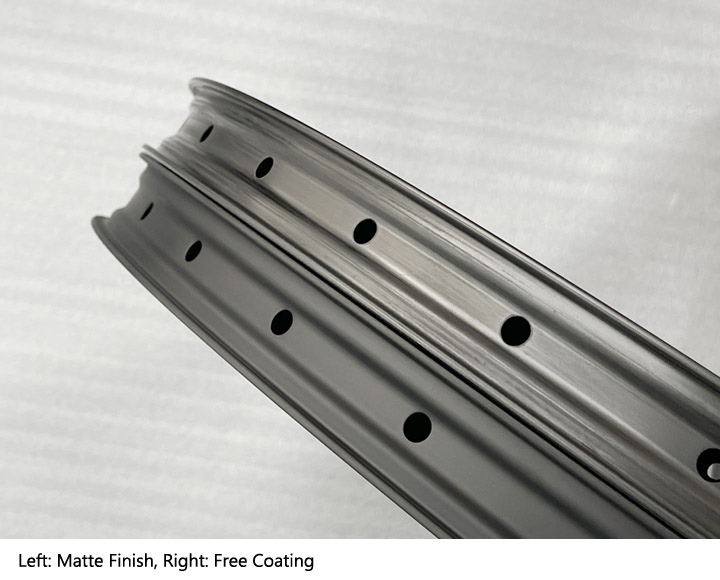

Free Coating Manufacturing (FCM) process is a newly developed process in manufacturing carbon fiber rims, no sanding or finish coating process conducted on rim surface. Rims get polishing treatment right after the raw ones come out from the rim molds. It can also be called Free Painting. The FCM process has been quite mature, now we formally introduce this new manufacturing process. All of our carbon fiber rims now are available with FCM process. The advantages of an FCM processed rim are listed as below:

Advantages:

1. Better Quality.

Since no sanding process conducted on rim surface by the sand paper, there is no risk of hurting carbon fiber materials over the rim surface. Quality and strength could be highly guaranteed.

2. Lighter Weight.

Since no finish coating added onto rim surface, the weight of a rim could be lighter at 5-20g according to different model of carbon rims.

3. Scratch Resistance.

The resin between carbon fibers performances a better scratch resistance than the finish paint, so a rim with FCM process performances a better scratch resistance than a rim with finish coated.

4. Environment-friendly.

Because of saving the processes of sanding (which causes dusts) and finish coating (which causes pungent smell and air pollution), it's quite friendly to natural environment.