Introduction: Road Rim the Top —— Alpha 50 Carbon Fiber Bicycle Rim

In the relentless pursuit of carbon fiber bicycle rim innovation, NEXTIE continues to break boundaries. Now please allow us to introduce this top-level newly designed road rim —— Alpha 50.

For top-level road bike rims, it is different from mountain bike rims. Light weight is not the primary goal for road rims. The goals of road rims are to achieve a balance between optimizing the weight of the rim and ensuring a certain rotational inertia, excellent dynamic balance, sufficient stiffness to make the rim achieve a smaller deflection, better wind-breaking performance to increase riding speed, and greater strength. The newly launched Supreme Edition Alpha 50 carbon road bike rim embodies our revolutionary solution, incorporating multiple core technological innovations.

1. Advanced Single-Point (ASP) Reinforcement at Spoke Holes and Valve Stem Hole, Rims being Lighter and Stronger.

We specially designed the rim shape at the spoke hole position, developed the advanced single-point reinforcement technology specifically for Alpha 50, which results in rims that are lighter and stronger, 335g only. At the same time, this new design gives us more maneuverability, distributing the weight more toward the edge of the rim, thereby increasing the rotational inertia of the rim, which plays an important role for a top-level road bike rim.

|  |

2. Material Breakthrough: Toray T1100 + M46J Aerospace Grade Carbon Fiber, Further Improving Performance.

Alpha 50 pioneers the use of Toray T1100 and M46J aerospace-grade carbon fiber as its main structural material, making rim much stronger. This is the first time we apply "M-series" carbon fiber materials to manufacture bicycle rims. As we know, the terms "T-series" and "M-series" refer to classifications of Toray carbon fibers, specifically T-series for tensile strength and M-series for modulus (stiffness). M46J has better stiffness performance than T-series like T800, T1000 or T1100. The addition of M46J materials can effectively improve the rotational deflection and stability of the wheels.

3. Newest Layer-up Structure: All-Wrapping Technology & Optimize Wheel Weight Distribution to Improve Wheel Rotation Inertia.

We reduce the weight of Alpha 50 by the advanced single-point reinforcement design on the spoke hole side and materials improvement. On the rim bed side, we apply the latest layer-up structure to optimize weight distribution, which results in the high improvement of rim's rotational inertia. At the same time, all-wrapping technology (AWT) for main carbon fiber structure applied on Alpha 50 further improves the stability and stiffness. AWT ensures the integrity of the carbon fiber material, thereby ensuring the rim's stability and stiffness. AWT is also applied on our road bike rims of Ripple series and Ocean series.

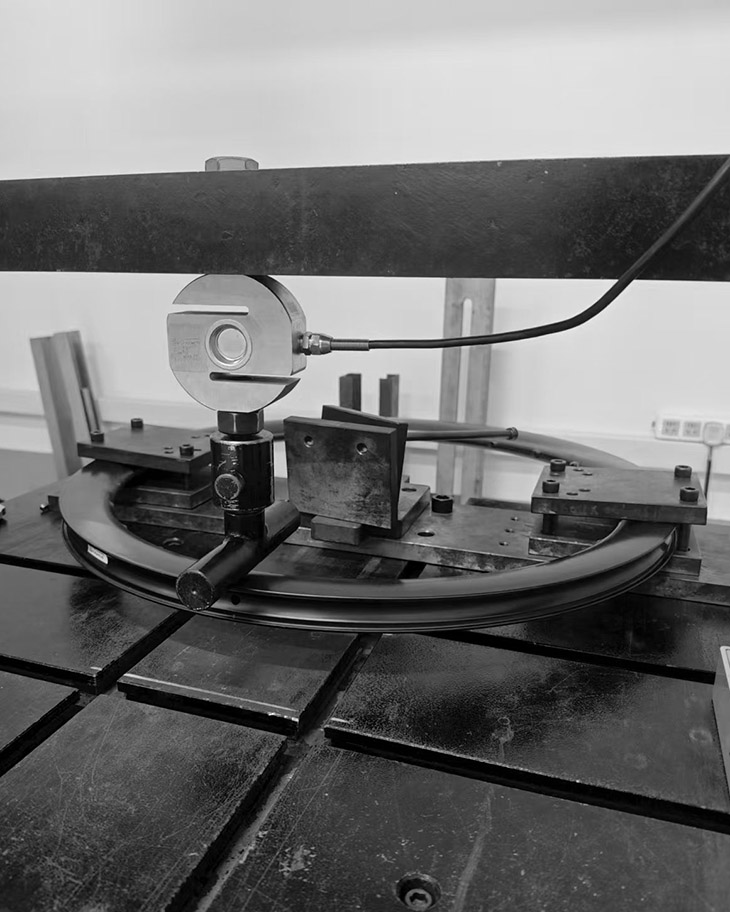

4. Highly Strict Technical Test Methods — 110J (UCI test condition).

We applied the UCI test conditions to test Alpha 50 carbon rim. The impact test result was 110J. This is much higher than the UCI's qualified strength standard for road bicycle rims. This strength performance is almost close to ASTM Classification Condition 4. IMPACT TEST VIDEO.

Beyond these core innovations above, Alpha 50 carbon rim incorporates numerous advanced manufacturing techniques including precision carbon fiber cutting, optimized mold materials, refined production processes and wheelset temperature test under 80 ℃ for 4 hours - collectively establishing Alpha 50 carbon rim as the ultimate road bike competition-grade product.

This rim could be used for Road. Triathlon. Cyclocross. Dirt. Gravel and Adventure riding. The tire size for this model of rim is recommended at 28 ~ 53mm Road / 28 ~ 40mm Cyclocross / 28 ~ 60mm Gravel. The tire pressure is recommended at 30 ~ 90psi Road / 25 ~ 54psi Cyclocross / 27 ~ 79psi Gravel.

Positive Stiffness Test

Lateral Stiffness Test

|  |

Spoke Tension Test

Wheelset Assembly

|  |

Impact Test

Product Information

Additionally, on October 8th of this year, the Alpha 50 wheelset was awarded UCI quality certification. The information is published as follows:

WHEEL-APPROVAL-PROCESS-CERTIFICATE-NEXTIE-ALPHA-50.pdf